Yes, If the luminance contrast between the substrate and the Stair Nosing riser is less than 30%.

Yes, ESP are able to deliver products nation-wide.

From the date of purchase, ESP Australia will warrant the ESP Access® Tile products for their designed life expectancy, which is as follows:

- Low Pedestrian Foot Traffic (6-10 years)

- Medium Pedestrian Foot Traffic (3-5 Years)

- High Pedestrian Foot Traffic (1-2 Years)

Salt will not affect our Tactile Indicators. Extensive testing has confirmed salt, chewing gum and aerosol paint can be removed with cleaning solutions.

It is not recommended that our Tactile Indicators be installed on top of asphalt. The recommended solution, however, is to cut a section of asphalt, pour concrete, and then embed the ESP Access® Tile in the wet set concrete. For more information regarding this topic please see our blog article - Installing TGSI’s On Asphalt – What do I need to know?

Yes, ESP is able to offer LRV Testing to any internal or external project. Please contact us today to find out more or to arrange a quotation.

Each ESP Access® Tile is manufactured through a high-pressure compression process of a sheet moulding compound (SMC). Produced with our unique ‘Herculite’ material, we construct every ESP Access® Tile with the highest quality components and with additional UV stabilisers for the harsh Australian sun. This ensures that the Access® Tile will maintain it’s durability and its individual Luminance Contrast Values over the long term.

Yes, we provide installation training or demonstrations for our Tactile Ground Surface Indicators for anybody who requires it, upon request. This training can be provided for all of our AS/NZS1428.4.1:2009 compliant Tactile Indicators.

Installation instructions for ESP’s surface applied & cast in place Tactile Indicators can be found under the ‘Tactile Indicator’ section of our website menu. A video demonstration, step by step guide and pdf are all available to view.

According to Australian & New Zealand Standard AS/NZS 1428.4.1:2009 Design for Access and Mobility Part 4.1 – Means to Assist the orientation of people with vision impairment – TGSI’s, TGSI’s should be used at a ‘minimum’ in the following situations:

- Stairs & Stair Landings

- Escalators & Travellators

- Pedestrian Ramps

- Overhead Hazards (Including potential obstructions wall protruding fixtures)

- Carriageways without kerbs (I.e that intersect at the same grade)

- Railway, Tramway and light rail pedestrian – (Waiting platforms and level crossings)

- Waterbodies – (Wharves, lakes and ponds accessible by pedestrians)

Yes! ESP’s Access® Tile is specifically designed and rigorously tested, to meet and exceed AS/NZS1428.4.1:2009 requirements.

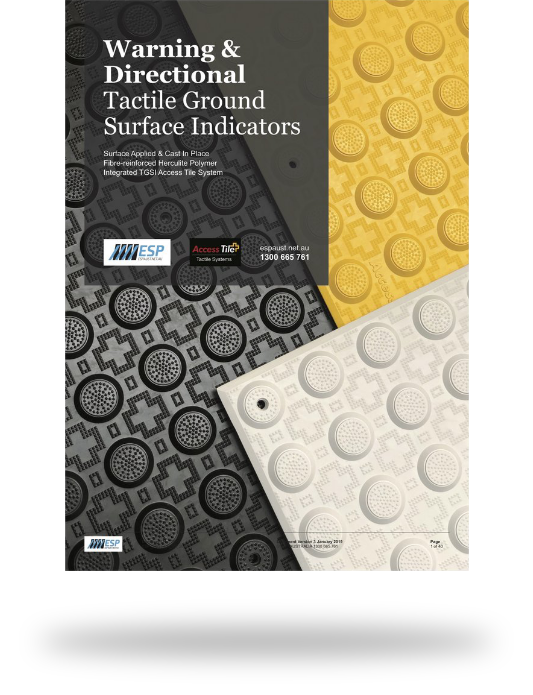

Each ESP Access® Tile is manufactured utilising UV stabilised & fibre reinforced Herculite polymers which provide superior durability as well as slip resistance, corrosion resistance and abrasion resistance.

These materials are used in both our wayfinding bars (Directional TGSI’s) and truncated domes (Hazard TGSI’s).

These materials are used in both our wayfinding bars (Directional TGSI’s) and truncated domes (Hazard TGSI’s).

- 600x300mm (Warning & Directional)

- 1200x600mm (Warning Only)

ESP Access® Tile’s are available in white, yellow & black.

When selecting a colour, consideration should be given to the luminance contrast between the substrate and the Tactile Ground Surface Indicator. For integrated TGSI’s, such as ESP’s Access® Tile, a minimum of 30% luminance contrast is required between the tile and the substrate.

Surface Applied – Tactile Indicators that are glued and screwed on top of any stable surface. They are fast to install, simple to retrofit and withstand the toughest pedestrian use.

Cast In Place – Tactile Indicators that are applied during the curing of wet concrete. When the concrete becomes cured, the ESP Access® Tile becomes mechanically fixed to the finished substrate.

Cast In Place – Tactile Indicators that are applied during the curing of wet concrete. When the concrete becomes cured, the ESP Access® Tile becomes mechanically fixed to the finished substrate.

Directional Tactile Ground Surface Indicators are a series of raised bars aligned to advise pedestrians of the direction of travel to a facility or point of service.

Warning / Hazard Tactile Ground Surface Indicators are truncated domes designed to warn pedestrians of hazards in the path of travel.

Tactile Ground Surface Indicators are truncated cones and/or bars installed on the ground or floor surface to provide cues, which, when combined with other environmental information, assist people who are blind or vision-impaired with warning or directional orientation information.

Each ESP Stair Nosing and Contrast Strip (SN&CS) is suitable to be chemically and mechanically applied to the finished surface.

ESP Stair Nosing’s can be supplied nationwide. For larger orders a forklift may be required at the point of delivery to accept and unpack the goods.

Stair Nosing & Contrast Strips can be cut to any length, up to 3 metres. ESP can advise on lengths to allow for expansion and water egress in external applications.

ESP’s anti-slip material incorporated into the product range is hard wearing and resilient to high volumes of foot traffic. It is produced using durable silicon carbide and can be used indoors or outdoors as they are UV & weather resistant.

The following tests have been passed:

- UL410 standard for slip resistance for floor surface materials

- AS/NZS 4586-2013 Classification: P5 the highest classification achievable.

The following products offered by ESP meet National Construction Code Compliance:

- F63 Series (PL) – Stair Nosing

- F430s Series – Stair Nosing

- N3 Series – Contrast Strip

- E14 Series – Contrast Strip

ESP’s photo-luminescent range of Stair Nosing and Contrast Strips contain pigment phosphors that absorb light energy and re-emit this as a bright glow when the lights dim or go out. Activated by either natural or artificial light, the ESP Stair Nosing products will glow for many hours following activation.

ESP uses a patented process to produce a range of products that provide a four-pronged solution to pathfinding needs:

- Step edge contrast

- Slip-resistance

- Visibility in all light conditions (Photo-luminescent)

- Resistance to wear

Stair Nosings & contrast strips are used to define the edge of a step, offering enhanced visibility and safety for all users particularly those with vision impairments.