At ESP, we have made it a goal of ours to provide safety products that deliver long term value for all users. Our industry leading range of Access® Tile Tactile Ground Surface Indicator’s are the result of extensive testing and development, premium compounds and materials, real construction ‘know-how’ and an unwavering commitment to excellence.

Supporting Australian Councils, Civil Contractors, Education departments and Building professionals we aim to improve accessibility in the built environment for all users.

Below is a quick guide to help understand Tactile Ground Surface Indicator’s and their applications.

What are Tactile Ground Surface Indicators?

Tactile Ground Surface Indicators are truncated cones and/or bars installed on the ground or floor surface to provide cues, which, when combined with other environmental information, guide and assist people who are blind or vision-impaired with warning or directional orientation information.

Category Types Available

Warning – Also known as ‘Hazard’ Tactile Ground Surface Indicator’s, are truncated domes designed to warn a pedestrian of a hazard ahead, such as:

- At a kerb ramp to warn where the footpath ends and the road crossing point begins.

- At a ramp or ramp landing to warn of the change in grade.

- At steps, stairs, escalators and at a change in direction on the footpath which includes directional Tactile Ground Surface Indicators.

Directional – A series of raised bars aligned to advise pedestrians of the direction of travel to a facility or point of service. They are installed:

- To give directional orientation to crossing points at intersections where the footpath width is greater than 3m distance measured from the property boundary to the top of the kerb ramp.

- To give directional orientation to kerb ramp crossing points within a raised traffic island.

- To give directional orientation across an open area.

- To give directional orientation to alert pedestrians of mid-block crossing points and at bus stops or tram/light rail stops.

Directional TGSI’s are installed either:

- With a single row of tiles (i.e 300mm wide) in the direction of travel between a “change of direction” plate and the top of a kerb ramp leading to a crossing point at an intersection or traffic island.

- With 2 rows of tiles (i.e. 600mm wide) across a continuing footway to alert people following the building line of a change of direction to a mid-block crossing point, bus stop or tram / rail stop. Note: The width of the TGSI’s ensures that the indicators will be detected as the typical width of a person’s step is generally less than 600mm.

ESP’s Surface Applied Access® Tile

ESP’s Surface Applied Access® Tile can be mechanically and chemically secured to any stable surface. They are fast to install, simple to retrofit and withstand the toughest pedestrian use.

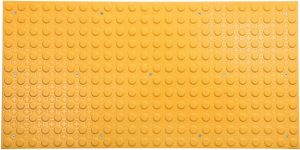

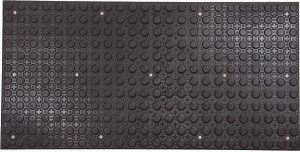

WARNING / HAZARD

300x600mm (White, Yellow & Black)

600x1200mm (White, Yellow & Black)

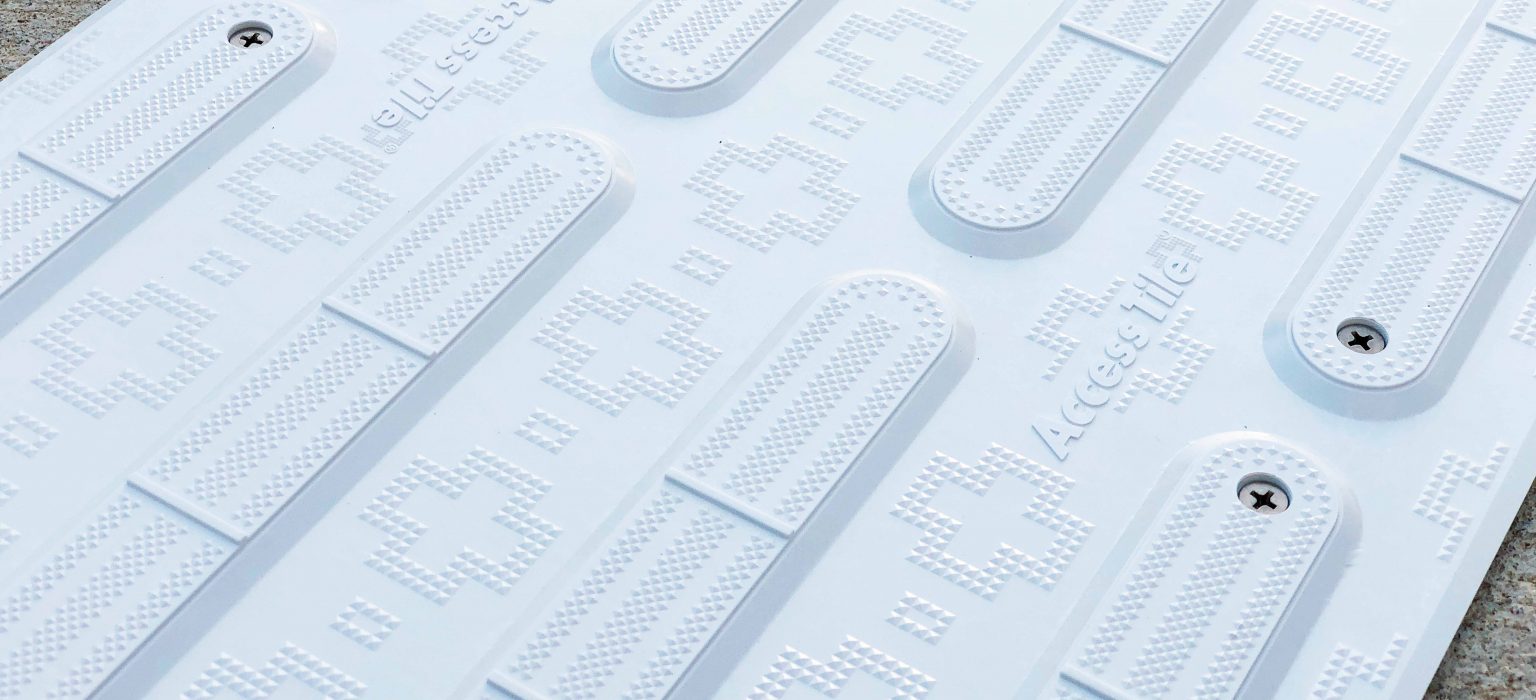

DIRECTIONAL

300x600mm (White, Yellow & Black)

ESP’s Cast In Place Access® Tile

ESP’s Cast In Place Access® Tile is applied during the curing of wet concrete. When the concrete becomes cured, the ESP Access® Tile is mechanically fixed to the finished substrate and is immediately trafficable.

WARNING / HAZARD

300x600mm (White, Yellow & Black)

600x1200mm (White, Yellow & Black)

DIRECTIONAL

300x600mm (White, Yellow & Black)

Application of Tactile Ground Surface Indicators – Where must they be used?

According to Australian & New Zealand Standard AS/NZS 1428.4.1:2009 Design for Access and Mobility Part 4.1 – Means to Assist the orientation of people with vision impairment – TGSI’s, TGSI’s should be used as a ‘minimum’ in the following situations:

- Stairs & Stair Landings

- Escalators & Travellators

- Pedestrian Ramps

- Overhead Hazards (Including potential obstructions wall protruding fixtures)

- Carriageways without kerbs (I.e. that intersect at the same grade)

- Railway, Tramway and light rail pedestrian – (Waiting platforms and level crossings)

- Waterbodies – (Wharves, lakes and ponds accessible by pedestrians)

Luminance Contrast (TGSI’s)

Luminance Reflectance Value (LRV) is a measurement of the amount of light reflected from a surface. To comply with Australian Standards, TGSI installations must achieve a minimum Luminance Contrast between the TGSI and the surrounding substrate.

Tactile Ground Surface Indicators must achieve the following contrasts:

- 30% – Integrated Tiles (Such as ESP’s Access® Tile)

- 45% – Discreet (Individual TGSI’s)

- 60% – Composite Discreet (Individual TGSI’s usually with a different colour insert)

Now offering in-house testing, Contact Us today for LRV requirements to ensure your project meets Australian Code & Compliance.

https://esp-australia-media.s3.ap-southeast-2.amazonaws.com/wp-content/uploads/2021/09/09054332/Thumbnail-Things-you-should-consider-1.png

https://esp-australia-media.s3.ap-southeast-2.amazonaws.com/wp-content/uploads/2021/09/09054332/Thumbnail-Things-you-should-consider-1.png MUST KNOW – 5 Things to consider before choosing Tactile Ground Surface Indicators

Before you purchase or think about purchasing Tactile Ground Surface Indicators, you should consider the following. It could potentially save you thousands and avoid costly issues.

1. Making The Right Choice

With a variety of Tactile Ground Surface Indicator products on the market it is important to understand the pros and cons of each before making a final decision.

Common issues that Councils, Civil Contractors, Maintenance & Facility Managers come across when dealing with Tactile Ground Surface Indicators are:

- Colour Fading

- Cracking

- Peeling

- Lifting

- Poor Slip Rating

- Poor warranty support

These common issues are a result of poor design, poor product components, lack of product testing/development and cheap imitation products. This means that the products need to be replaced more frequently, costing asset owners and taxpayer’s significant amounts of money. The downside to Tactile Ground Surface Indicators not performing is the negative impact to the intended end users of the product – people with vision impairment.

Ceramic – Tactile Ground Surface Indicator’s

Perceived Advantages – Cost-effective, widely available

Issues – Poor slip ratings, easily damaged, expensive to install, unsafe when damaged.

Bladed Shaft – Tactile Ground Surface Indicator’s

The picture below demonstrates how easy it is for the inserts to dislodge rendering the Tactile Ground Surface Indicators non-compliant.

Perceived Advantages – Cost-effective relative to stainless steel individual Tactile Ground Surface Indicators.

Issues – Fades, short product life cycle, substrate needs to be cut, easy dislodgement, specialised equipment required for installation.

Stainless Steel – Tactile Ground Surface Indicator’s

Perceived Advantages – Architectural appeal, internal use.

Issues – Expensive, slow installation and removal process, easy dislodgement.

Plastic Pad – Tactile Ground Surface Indicator’s

The picture below demonstrates how much the tiles have faded & how poor the colour contrast is between the Tactile Ground Surface Indicators and the concrete substrate. The tiles have peeled and lifted and are now unsafe for all pedestrians.

Perceived Advantages – Cost-effective, readily available

Issues – Crack, peel, fade, lift, safety of users

2. Longevity – Will it last a long time?

Ask yourself the question… Will these Tactile Ground Surface Indicators last a long time?

ESP Australia are proud to supply Australian councils and civil contractors with the most innovative and reliable fibre reinforced ‘Herculite’ polymer Tactile Ground Surface Indicators on the market. This has been achieved through subjecting our designs and materials to over 24 International and Australian Standards independent tests. Meaning the Access® Tile will maintain its strength, durability, and colour over the long term.

Say goodbye to lifting, peeling, fading, and cracking Tactile Ground Surface Indicator’s with ESP’s Access® Tile!

3. Installation time & labour costs

It is also important to factor in installation times and labour costs. Some Tactile Ground Surface Indicator products require special tooling and machinery to be installed and can be very time consuming and slow.

ESP’s Surface Applied Access® Tile is designed to be fast and easy to install utilising both adhesive and fixings for a secure bond between the tile and the substrate. The Access® Tile can be installed onto ANY stable surface and is now available in a 1200x600mm (Warning Tile) to increase efficiency and speed.

Additionally, ESP offer a Cast In Place Tactile Indicator product which can be installed in minutes during the concrete finishing stage.

4. After sales service & warranty support

You really do get what you pay for when it comes to Tactile Ground Surface Indicators…

At ESP Australia we live by our mantra and are always looking to ‘Be the solution’, assisting with any problems you may encounter. Our Tactile Ground Surface Indicator products are designed to last, which is why we back them with our comprehensive warranty.

From the date of purchase, ESP Australia will warrant the ESP Access® Tile products for their designed life expectancy:

- Low Pedestrian Foot Traffic (6 – 10 Years)

- Medium Pedestrian Foot Traffic (3 – 5 Years)

- High Pedestrian Foot Traffic (1 – 2 Years)

5. Are they easily replaceable?

Using certain types of Tactile Ground Surface Indicators can prove to be a costly exercise later down the track when it comes to replacing tiles. This should be something to consider when selecting types of Tactile Indicators.

ESP Australia’s Cast In Place Access® Tile has been designed with this in mind utilising corrosion resistant hexagonal anchors which are designed to trap concrete for optimal anchoring. By simply removing 5 screws the tile can be lifted out of the set concrete and replaced with a brand-new tile. The replaceability feature of the tile is industry leading due to its simplicity and speed.