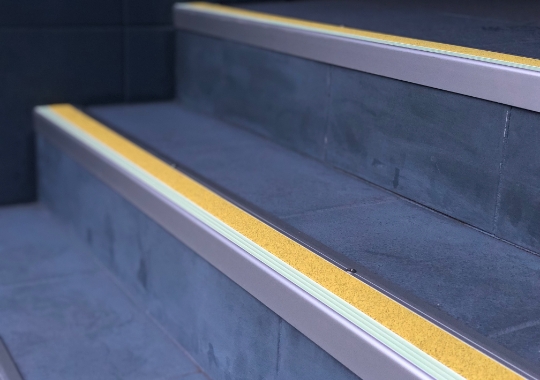

Reducing Slips, Trips & Falls

ESP Australia’s Stair Nosing and Contrast Strip systems are a robust and resilient addition to safety and risk prevention in your built environment. Made to measure and a design to suit any application, ESP Australia stocks National Construction Code Compliant edging with independant slip resistant testing to AS/NZS4586.

How Does ESP Stair Nosing Work?

ESP uses a patented process to produce a range of products that provide a four-pronged solution to pathfinding needs:

- Step edge contrast

- Slip-resistance

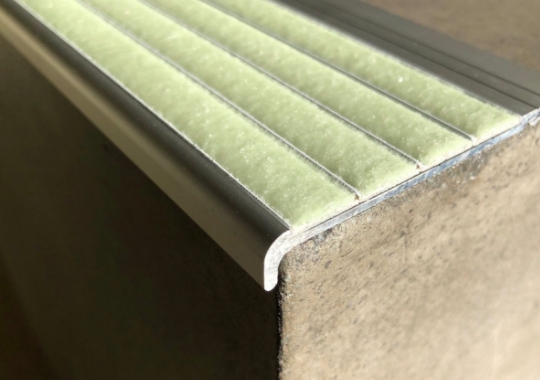

- Visibility in all light conditions (PL)

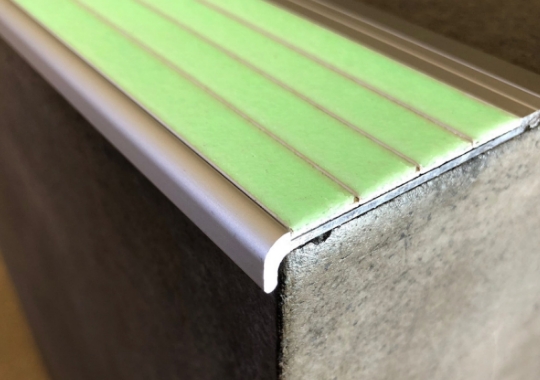

- Resistance to wear

How Does Photo Luminance Work?

Some of the ESP Stair Nosing and Contrast Strip products contain photo-luminescent pigment phosphors that adsorb light energy and re-emit this as a bright glow when the lights dim or go out. Activated by either natural or artificial light, the ESP Stair Nosing products will glow for many hours following activation.

Slip

Resistance

ESP’s anti-slip material incorporated into the product range is hard wearing and resilient to high volumes of foot traffic. It is produced using hard wearing silicon carbide and can be used indoors or outdoors as they are UV & weather resistant.

The following tests have been passed:

- UL410 standard for slip resistance for floor surface materials

- AS/NZS 4586-2013 Classification: P5 which is the highest classification achievable.

Why Do ESP Stair Nosing’s & Contrast Strips Perform So Well?

Each ESP Stair Nosing and Contrast Strip is manufactured through the method of aluminium extrusion and natural clear anodising.

Each tread shall have a strip not less than 50mm and not more than 75mm deep across the full width of the path of travel. The strip may be set back a maximum of 15mm from the front of the nosing. The strip shall have a minimum luminance contrast of 30% to the background. Where the luminous contrasting strip is affixed to the surface of the treads, any change in level shall comply.

Our Partnerships